Vitrification

(PAGV)

Ash and Asbestos Vitrification for Liability Mitigation

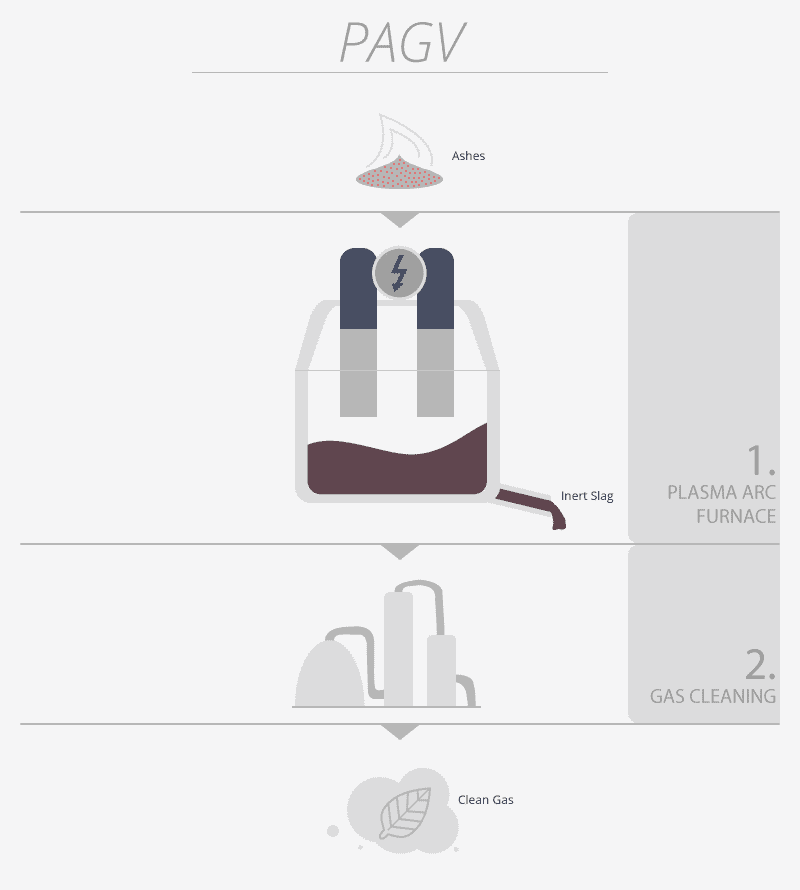

As the forerunner for our game-changing PRRS waste-to-energy technology, our Plasma Arc Gasification and Vitrification (PAGV) system converts incinerator ash and other hazardous inorganic material to an inert slag. PAGV eliminates future legacy issues for operators of incinerators with a simple melting process for their grate and fly ash and turning it into a useful construction material. Municipalities, along with managers of incineration operations for industrial, hazardous, biomedical, and animal (slaughterhouse) waste, all can profit from our PAGV by turning their hazardous ash into a non-toxic vitrified slag which can be used in wide-ranging applications: aggregate asphalt and flooring, partial replacement for cement in concrete, and even jewelry. Asbestos waste from decommissioning operations is also an excellent use for the technology. Our PAGV system is available in capacities ranging from 1 to 250 metric tons per day per module.

BENEFITS:

- Processes grate ash and fly ash generated from a wide variety of waste combustion processes (MSW, hazardous, biomedical, etc.), as well as other inorganic waste streams such as asbestos from decommissioning and site clean-up operations

- No liabilities from improper ash or asbestos disposal

- Reliable, easy-to-operate and maintain with minimal manpower requirements

Using our unique furnace design, this proprietary arc plasma technology used graphite electrodes and an electrical current to create arcs between the electrodes and the melt. This generates an extreme temperature environment above 1600°C. The feed waste (ash, asbestos) is then transformed into a glassy slag which when removed from the reactor and cooled, is inert and non-toxic. This slag has been demonstrated to be effective as a building material for construction.

HOW IT WORKS :